Thermal Fan Clutch Diagnosis

Many times when an engine overheats, the easy answer is to replace the thermal fan clutch. This doesn't always solve the problem of overheating.

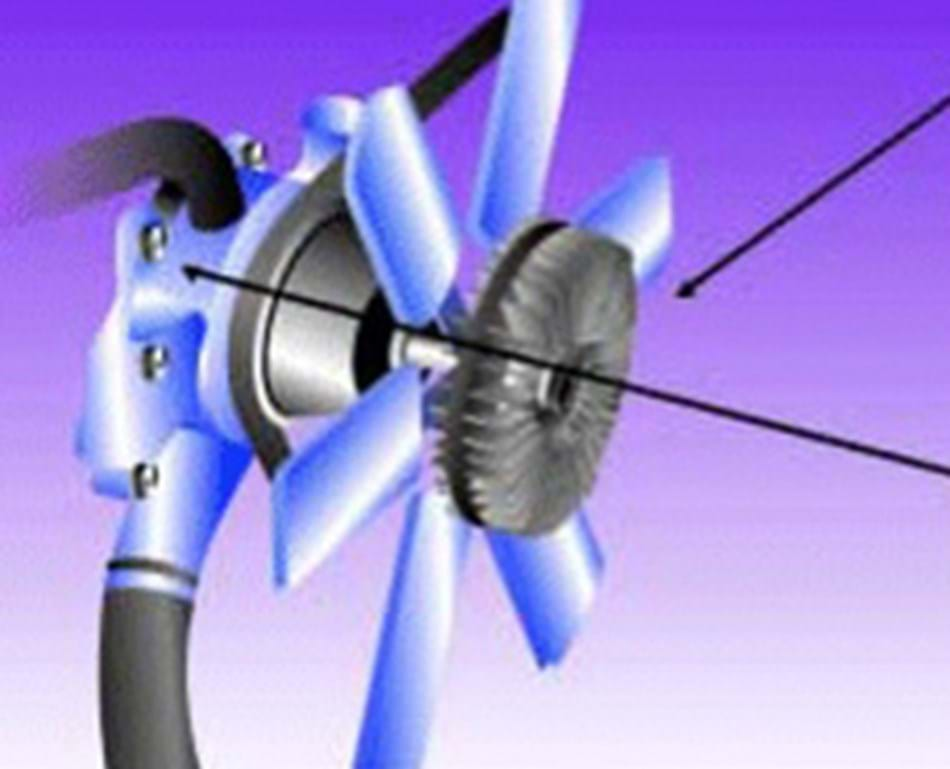

To properly diagnose fan clutch issues you need to understand how it functions. When cooling is not needed, the fan clutch is disengaged. As the pulley spins, typically driven by the belt, the fan is driven at a minimal speed (usually 10 to 20 percent) reducing drag on the engine. As the coolant heats up, the air passing through the radiator increases in temperature. The hot air passing over the bi-metal spring causes the coil to expand. This moves internal components inside the fan clutch allowing the silicone fluid to pump into the drive area. Silicone generates friction in the drive area causing the fan clutch to engage, thus driving the fan to a higher percent of the pulley speed (anywhere between 60 to 90 percent). Once cooling is achieved, the bi-metal spring contracts, closing off the flow of silicone. This reduces the friction allowing the fan to spin at a lower percent.

We do not publish the temperature range of the bi-metal spring. This is to make sure that no one attempts to measure the temperature of the air crossing the fan clutch face, which could cause personal injury.

PROPER DIAGNOSIS PROCEDURE: Start with a cold engine. The thermal fan clutch will be engaged for a short period of time during engine warm up. This length of time depends upon the duty and/or specifications of the vehicle tested. When air temperature is sufficient enough to activate the bi-metallic spring, the fan clutch should engage. Air flow is critical; check for any obstructions or limiting factors such as, shrouds and air dams present, radiator and condenser free of debris, cooling system properly maintained, and the fan blade has no bent/cracked/chipped blades. At cold startup, the pitch of the fan blade controls how fast the clutch disengages .

To measure the pitch of the fan blade, place it on a flat surface and measure the vertical height of the blade. If the vertical height is 2.5 inches, or greater, the fan blade will require a heavy-duty clutch. If it is less than 2.5 inches, the blade will need a standard duty clutch. When installed, the tip of the fan blade should move forward and backward no more than ¼ inch. Keep in mind that a fan clutch shares a common service life as a water pump and should be replaced at the same time.

Lack of disengagement can be an issue as well. Commonly, excessive fan noise is noted by the vehicle occupants, as well as some cooling issues. A fan clutch that will not disengage will continue to try to cool the engine when no longer needed. Later model vehicles can suffer from a check engine light for the coolant not reaching operating temperature (commonly a P2181 or P0128). Care should be taken to ensure the correct fan clutch is installed on the vehicle as each clutch disengages at a specific temperature with a specific fan blade. Hotspots in the radiator, lack of airflow across the bi-metal spring, or other airflow obstructions can alter the performance of a fan clutch and cause disengagement issues.